We engage our potential customers at the early stage of their products introduction, injecting our knowledge base into their products, so as to ensure cost effectiveness and quality of their final products. We work with customer to do detailed root cause analysis and corrective action plans at each stage of proto runs, pilot run and the final Qualification Run, prior to Mass Production.

We are a strong believer in Doing it Right from the Get Go.

We have a technically strong and dedicated NPI team, coupled with great communication and management skills to ensure all our customers’ products are introduced in Time and Quality.

We look forward to growing the business with our Customers.

Strategic Location

Dynamic Team

Equipped with State of the Art Surface Mounting Technology, incorporated with component level traceability. We provide our customers with the flexibility and agility without compromising on quality and productivity

Our Surface Mount manufacturing capabilities includes:

Surface Mount Technologies (SMT)

Auto Insertion

Plated through Hole and Wave Soldering

Our team supports hardware and software in house Test Systems Development. We are capable in many software platforms which enable flexibility of solutions to meet customer requirements.

We are accomplished in:

Quality is our Passion

BCM is passionate to strive for highest quality levels for our customers through our executions in quality planning, initiatives in driving continuous improvement and working with our customers in achieving the ultimate goals.

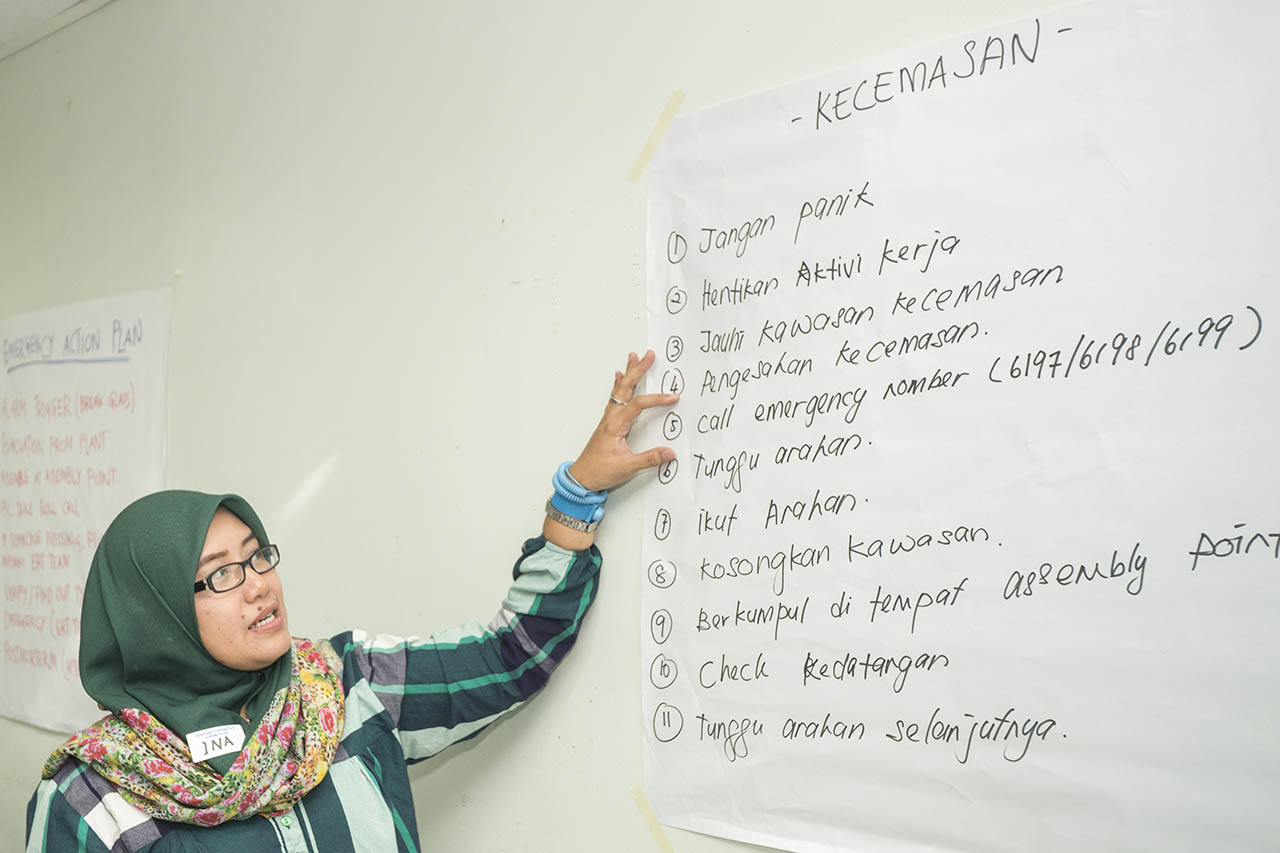

Our experienced team executes our established operating procedures, ensuring our quality policy is effectively communicated to all levels. We emphasize customized quality plan for our customers, with validated in-house developed systems, subject matter expert in our fields and proven continuous work applications, in ensuring we are compliant with all applicable industry requirements. We undergo regular global TUV quality management system audits and proactively studies and research in implementing the best practices available, in order to stay ahead in the industry.

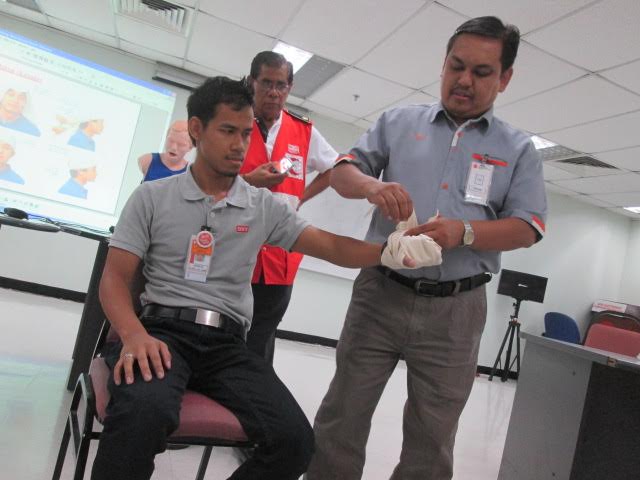

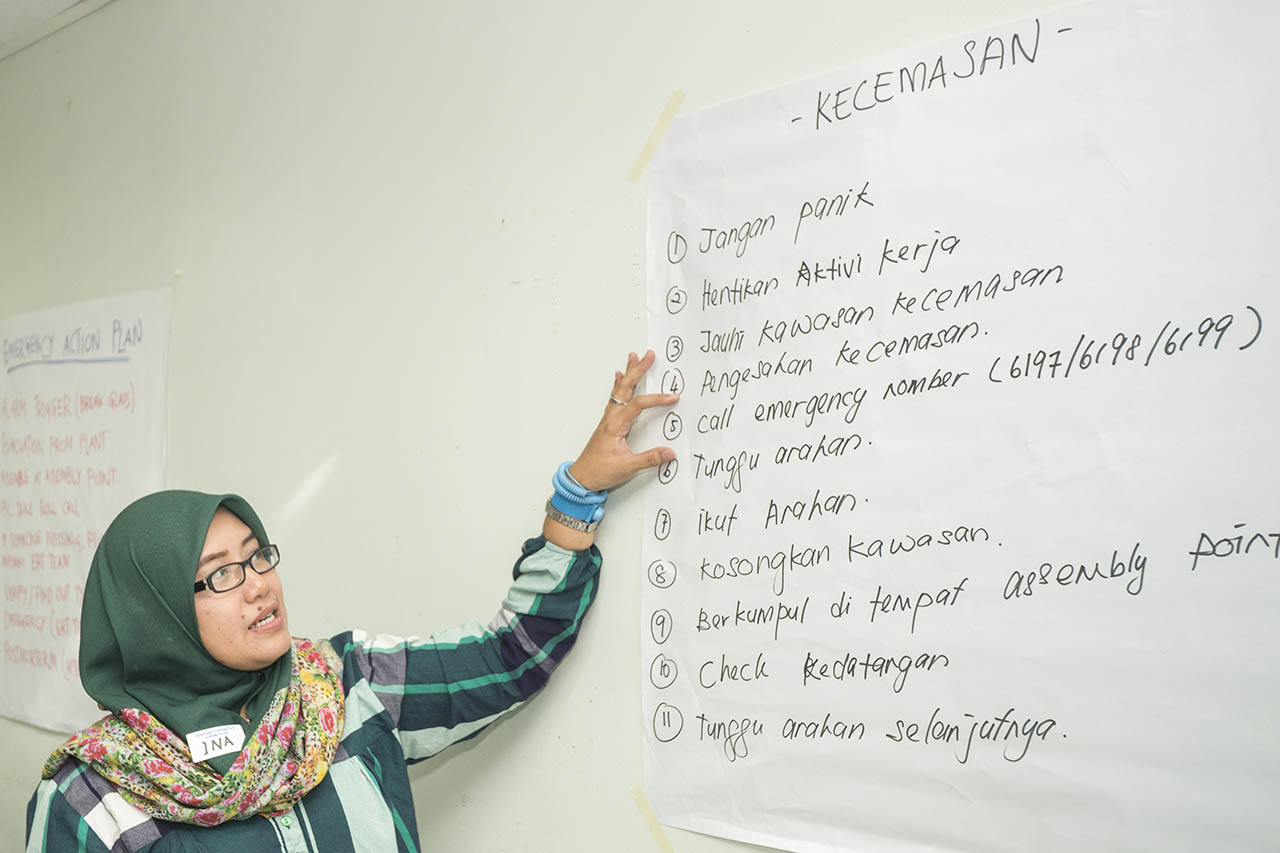

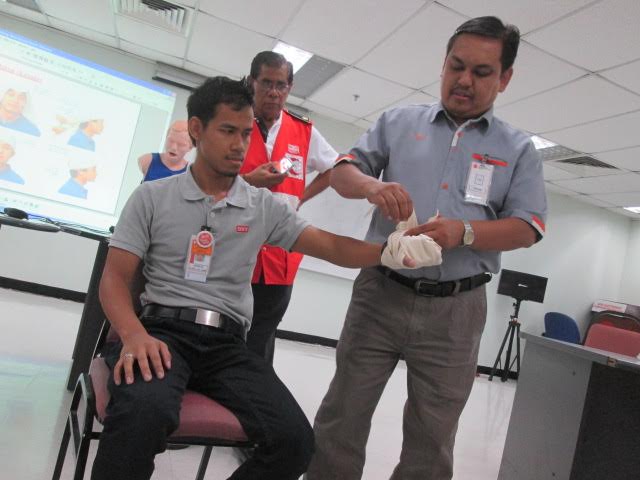

Through deploying advance quality plan and measureable metrics, we develop the zero defect culture through proactively involving all levels of employees to mitigate risk and promoting seamless processes through execution of lean practices. Our designed trainings for our valued employees continuously steering the momentum to motivate and strive for better manufacturing processes that yields better product quality.

That, makes us an EMS with a difference.

Our Quality Certifications:

BCM offers our services as a One Stop Turnkey Solution, from Development, Sourcing, Procurement, NPI to Manufacturing and shipments to customers.

Our Specialty includes

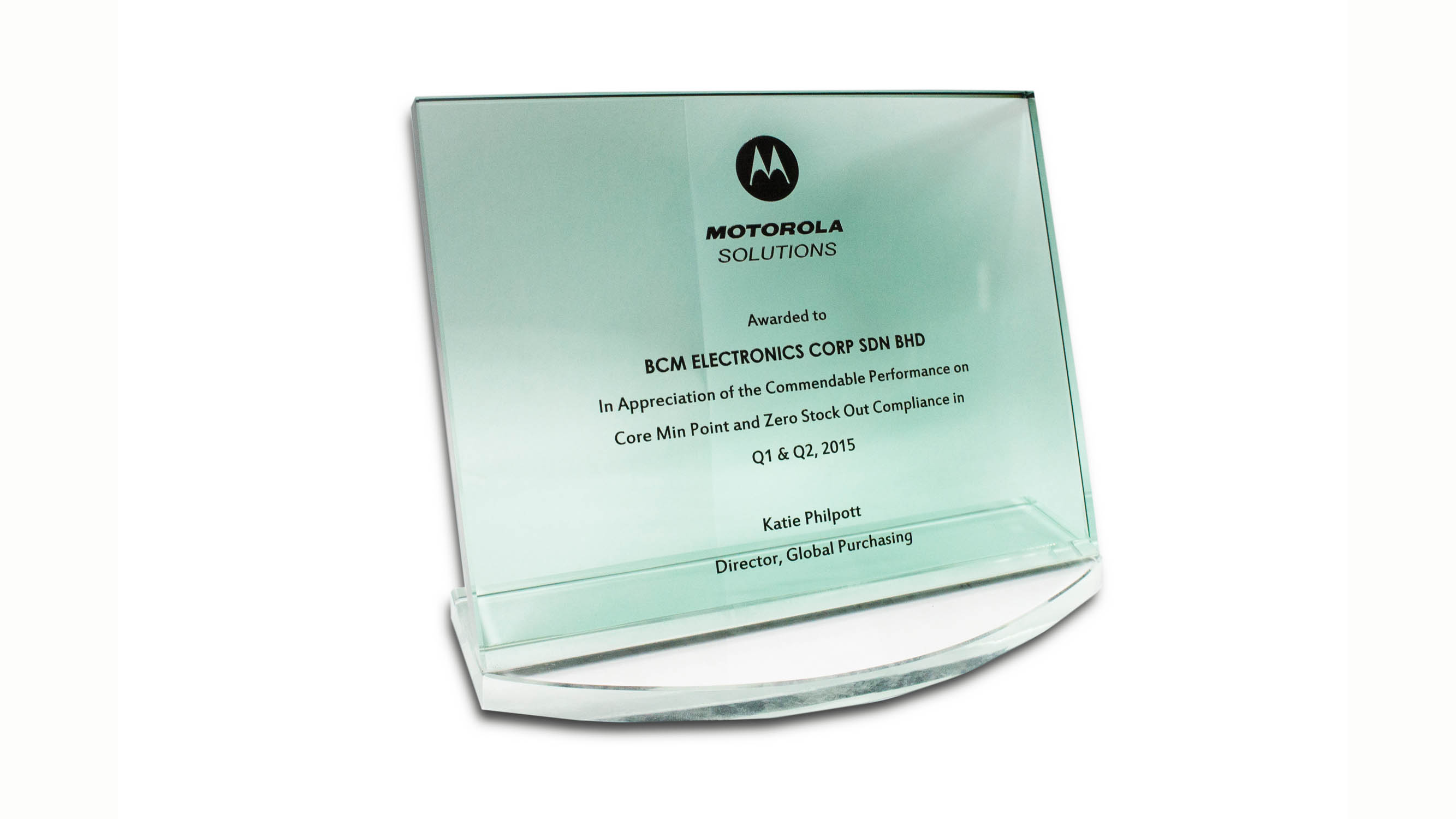

In our pursuit towards Excellence and Customer Satisfaction, we continuously upgrade our technology, capability, Business Integrity and Ethics.

We are a matured organization with experienced employees, incorporating Environmental Protection and Corporate Social Responsibilities in our drive to success.

Our diverse background allows us to provide our customers with innovative, smart, cost effective and timely solutions.

Our experienced team is equipped with the right tools, knowledge, Six sigma and Lean manufacturing to address all engineering challenges.

Strength

Mission Critical

Public Safety

Remote Safety

LED Street Lighting

LED Domestic Lightings

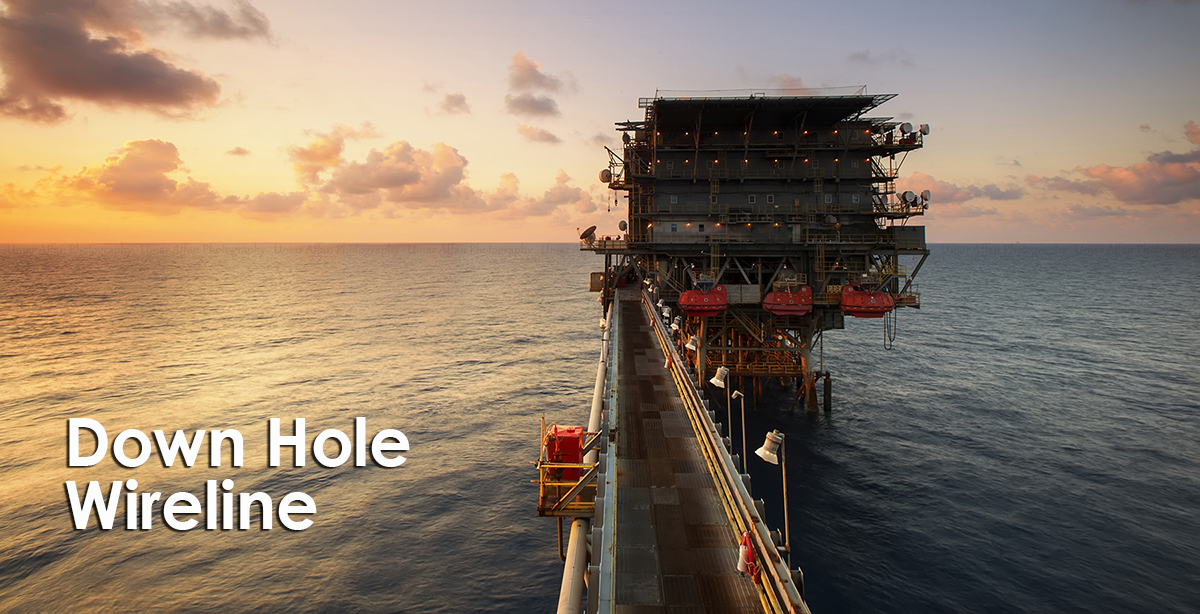

Down Hole

Wireline

Global or Regional Mobile and Remote Monitoring

DC – DC Converters

AC- DC Converters

Lighting Control

At BCM, we do not compromise on quality and continuously promotes improvements via creative and innovative ideas. Our goals are fully supported by excellent quality manufacturing executions in delivering & meeting customer’s satisfaction, structured quality management system, health & safety management and comprehensive employee involvements.

We are also driven by an immense impulse in training and research from the very beginning, by the untiring pursuit of ever better solutions. These are reflected through our previous and current projects, hence our achievements throughout the years of excellence.

Beyond technologies and systems: We always put the best interest of our employees, community and environment as the key part of our company goals. Our corporate social responsibility for the community and the environment is part of our daily business in creating shared values for business and society.

We are committed in delivering the highest level of services and values.

BCM Electronics Corporation is a medium size world class Electronics Manufacturing Service provider with 32 years of experience in the industry and specializing in high mixed-low volume product.

We provide SMT & box build services to MNC's worldwide, some of whom have been with the company since its inception in 1993.

The products we manufacture includes RF Communications, Power Electronics, Oil & Gas, Automotive and Lightings.

Our capability includes IPC up to Class 3, ROHS compliance and we take pride in our focus on environmental protection as part of our business.

Located in Kulim Hi Tech Park Kulim Kedah Malaysia, our manufacturing site is 436,000 Sq ft large with a build up area of 203,000 Sq ft. with over 1200 employee.

Gathering of dedicated people in achieving full quality products, our team is the most distinguished people in their expertise with absolute commitment and continuous improvement to provide customer satisfaction.

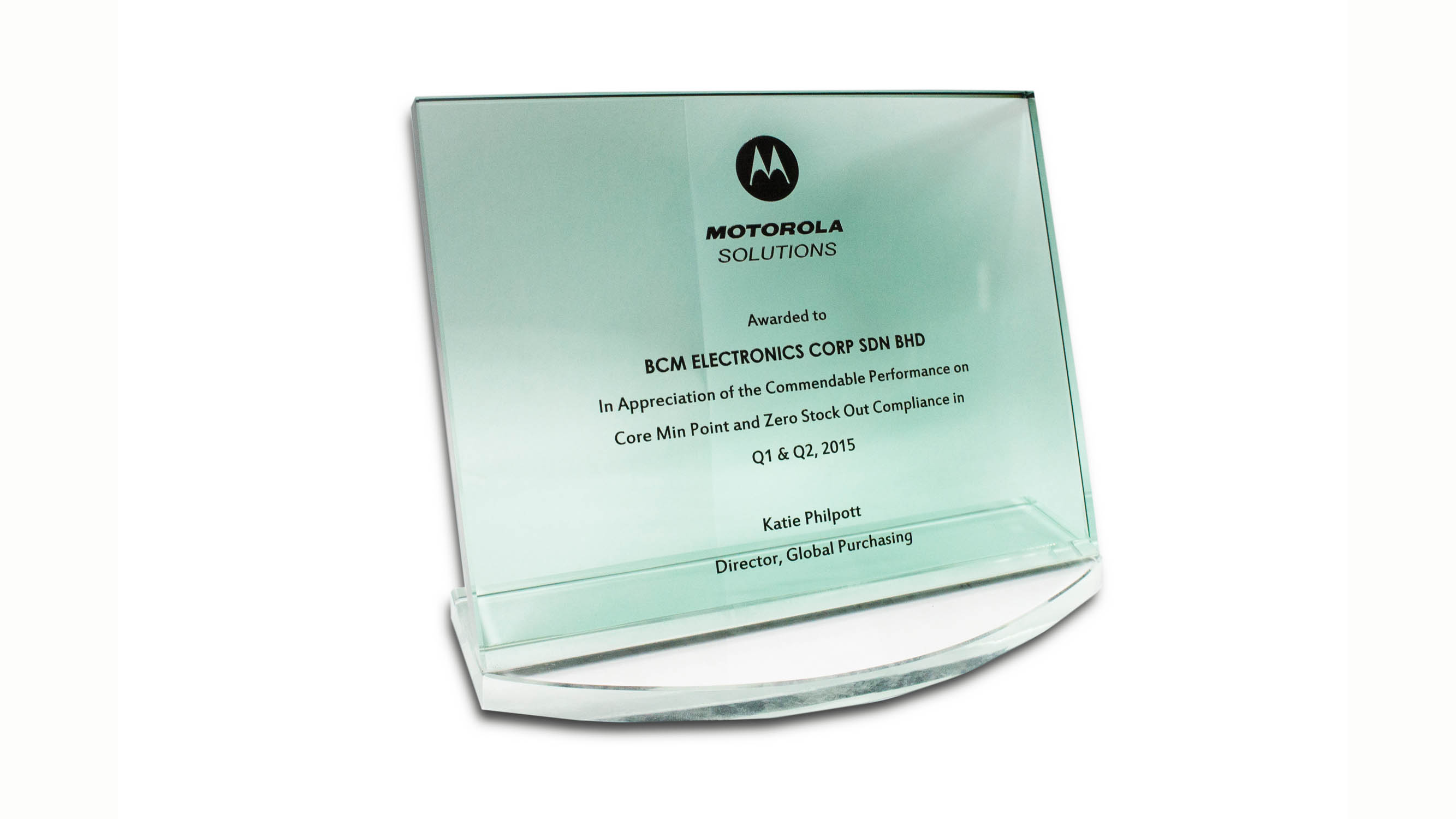

Promise of Integrity is an alliance of companies started in 2016 to focus on upholding the highest standards of ethics and integrity within the business community.

On 16 August 2016, Intel Corporation, B. Braun Medical Industries, Keysight Technologies, Motorola Solutions and SilTerra Malaysia collaborated in a ‘Promise of Integrity’ event to spearhead an initiative on ethics and integrity. This marked the beginning of a joint effort to lead the way in upholding the highest standards of integrity.

BCM Electronics Corporation Sdn Bhd is part of The Promise of Integrity supplier alliance, which was formed in July 2017 to enhance collaboration within the supplier ecosystem in creating and upholding the highest standards of ethics and integrity.

VISION

Integrity, our Global Competitive Advantage.

MISSION

Transforming the supply chain into a globally competitive business environment by enabling the highest standards of ethics and integrity.

“ Integrity and Ethics are the foundations of a company’s performance reliability and consistency. Without integrity and

ethics, a company’s value, trust and social status are compromised. BCM strongly supports the agendas of Promise Of

Integrity”.

CY Lee

CEO

BCM Electronics Corporation Sdn Bhd

1.Buyer Analyst

Job Responsibilities

Skills and Qualification

2. Sourcing Officer

Job Responsibilities

Skills and Qualification

3. Customer / Supplier Quality Enginner

Job Responsibilities

Skills and Qualification